A little over a year ago I got a 3D printer. I've had a great experience with it! I had printed a lot of lab hardware and some fun things, but then let it sit around for a few months while things were very busy in other parts of work. This past week was maker week in State College, so there were lots of 3D printing demonstrations around town and other maker projects. I decided I should get things fired up again. I've got a couple of new projects that will need custom enclosures built. Without being able to have a spot-welder in my apartment, I'm pretty much limited to plastics or paying for the manufacturing.

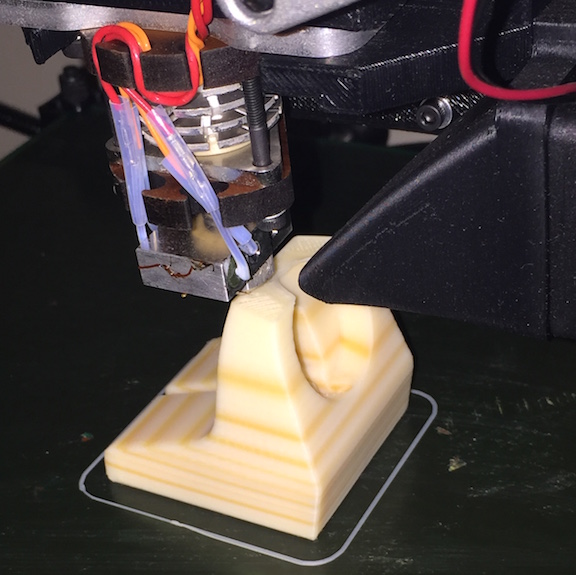

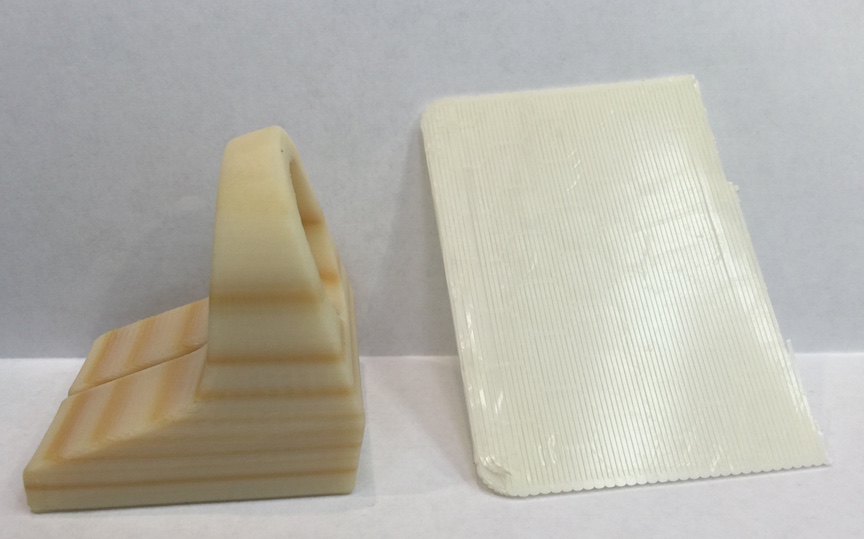

I re-leveled and calibrated the bed and z-axis mechanism. I carefully re-checked the extruder calibration to be sure that I got the appropriate amount of plastic extruded. Everything looked great, so I downloaded a simple, but utilitarian part for my Apple Watch off thingiverse. Using Slic3r, I created the GCode and sent it off to print. Everything started off like normal, so I left the printer running to deal with other tasks. I came back later and too many surprise the part had stripes!

I've always printed with ABS plastic. It's not that I don't want to use PLA, it's just what I've always had on hand and what I know how to work with. I happened to have left the white roll of plastic on the printer after my last print. Since my printer sits next to the window, it gets some sunlight, especially in the morning hours. Not the best location, but it's the only location I can place it for the moment. It looks like the UV radiation has damaged my filament! Every time the part of the roll that was exposed heavily comes around, I get a band. For a simple charging stand, I'm not too upset. I could even try some of the ABS bleaching brews used by antique computer collectors. I may just paint the whole thing with paint that matches my wooden night stand. Maybe this will give me a false wood grain look?

I wanted to confirm that the stripes corresponded to a revolution of the spool. The whole part is darker than parts printed from the same roll months ago, but I'd guess the darker bits were on the top of the roll. By analyzing the GCode that produced the part, I calculated that the printed used about 5.1 meters of filament (<$2). The roll has been used down to a coiling diameter of about 150 mm. That means I expect about 10-11 turns of the reel for the print. I see 7-10 layers depending on what I count, so I'll call that close enough.

Well that's the story for now. Don't leave your ABS in the sunlight, even on your machine. I've been meaning to get a dust cover for the machine and this is even more reason to do so and make sure it's opaque.

Pingback: 3D Filament and Humidity – Why My Prints Keep Failing | John R. Leeman